charpy impact test lab report abstract|charpy impact test sample dimensions : exporting Figure 2-1: Charpy impact tester, sample positioned in anvil and general testing results. This test has been used almost exclusively with body-centered-cubic (bcc) crystalline materials. These . webFoco e força. Exercícios aeróbicos para você melhorar seu físico e queimar calorias movimentando o corpo todo. Flex e Relax. Exercícios de flexibilidade corporal e mental para você trabalhar sua postura e equilíbrio.

{plog:ftitle_list}

WEB20 de nov. de 2022 · อ่าน Damn Reincarnation แปลไทย อัพเดทใหม่ ตอนล่าสุด บนเว็บอ่านมังงะ moodtoon เว็บอ่านการ์ตูนที่คัดแต่เรื่องสนุกมาให้อ่าน . ตอนที่ 76 .

Charpy Impact testing is used in studying material toughness and most importantly it indicates a material ability to absorb energy and plastically deform without fracturing. In this study, three .Emile Serebolo 18000405 ABSTRACT. In this investigation, we have taken a V .

Abstract. The Charpy impact test, just like any impact testing method, determines the toughness of materials by measuring the amount of energy absorbed by a specimen as it fractures while.

Figure 2-1: Charpy impact tester, sample positioned in anvil and general testing results. This test has been used almost exclusively with body-centered-cubic (bcc) crystalline materials. These .The document provides details on conducting a Charpy impact test to evaluate the mechanical properties of materials. It describes the theory behind impact testing, the key equipment used - including specimens, a Vernier caliper, .

Emile Serebolo 18000405 ABSTRACT. In this investigation, we have taken a V-notched mild steel specimen to test for the impact strength and the energy absorbed using the Charpy impact testing machine at room temperature. 1 Abstract In this experiment, the Charpy Impact test was conducted in order to determine the impact energy (K) absorbed by the Steel samples at 3 different temperatures. .

impact test report pdf

The Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and performance which are useful in engineering design, analysis of structures, and .

Students will perform Charpy tests on copper alloy and aluminum alloy specimens at temperatures ranging from -7°C to 95°C to determine the impact energy and percentage of shear fracture. Specimens will be notched and .The overall purpose of this research is to explore the usage of an impact testing machine, specifically the Charpy Impact Test device, to better understand the principles behind impact testing in order to further develop engineering skills .

The document provides instructions for conducting a Charpy impact test to investigate how the energy absorbed during deformation and fracture of metals varies with temperature. Students will perform Charpy tests on copper alloy .

specimen to the deforming or breaking specimen is equated to the "impact energy." The Charpy impact test uses a standard Charpy impact machine to evaluate this impact energy. The machine consists of a rigid specimen holder and a swinging pendulum hammer for striking the impact blow to a v-notched specimen as shown in Figs. 1 and 2.

charpy impact test specimen size

In a Charpy impact test to ISO 148-1, a notched metal specimen is severed using a pendulum hammer. For the test, the metal specimen is centered on the supports in the pendulum impact tester. The notch is exactly across from the .

charpy impact test department of chemical, materials and metallurgical engineering mmee 210: materials science lab 01: charpy impact testing names id kenosi . Laboratory Report Writing IN Chemical Engineering; CETG 211 Test 2 2016 Final; Rev+2006-combined-science+reduced; . Emile Serebolo 18000405 ABSTRACT. Charpy Impact Testing of Materials Abstract: The lab group were to perform impact force testing on the materials Steel 1018 and Aluminum 2024. The group were to test 5 samples of each product (10 total impact tests) at 5 different temperatures varying from -70⁰C with dry ice to 100⁰C boiling water to see how each material acted during numerous .

ENME 2711 SEC 001 Charpy Impact Test Laboratory Report Experiment I lab report submitted by: gabriel ranieri luxo LAB MEMBERS: GABRIEL RANIERI LUXO DATE EXPERIMENT PERFORMED: Wednesday, September 09, 2015 DATE REPORT SUBMITTED: Wednesday, September 30, 2015 Contents Objective 1 Introduction 1 Materials 1 Procedure 2 Results 2 .Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step-by-step Procedure of a Charpy Impact Test. Performing a Charpy impact test involves several important steps.

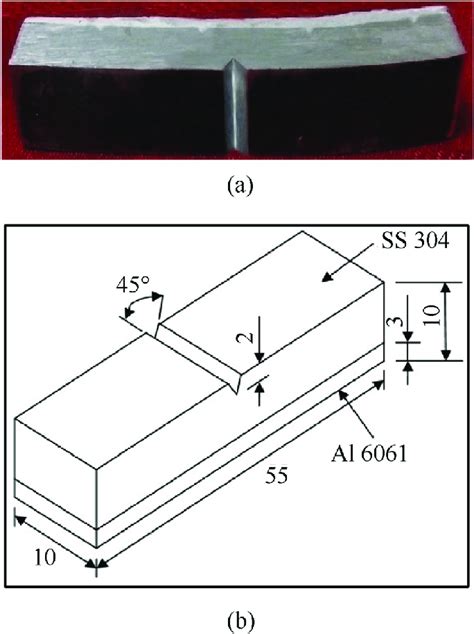

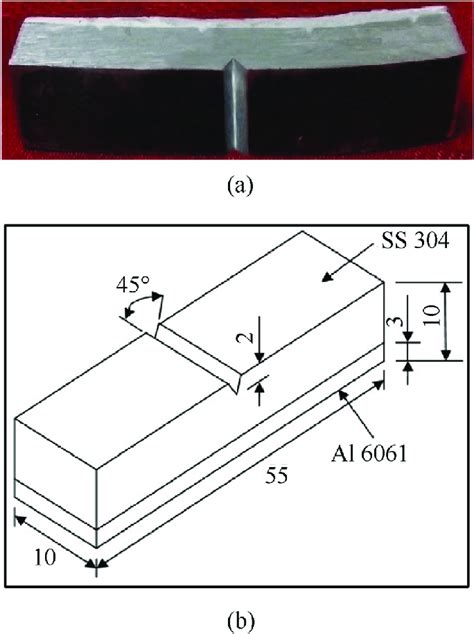

Charpy impacts test experiment no 9 lab report course name: ferrous metallurgy course number: mats 1021 21f section number: 04 experiment number: 09 experiment. Skip to document. University; . Ans: The Charpy impact value is calculated by dividing the fracture energy by the cross-section area of the specimen. So, area of cold rolled steel .Abstract The mechanical properties of materials are ascertained by performing carefully designed laboratory experiments that replicate, as nearly as practical, the service conditions. Factors to be considered include . (ksi), and CVN is the standard Charpy V-Notch impact test value. 3 Figure 1(a) and 1 (b) – Schematic Drawing of a Standard .

The Charpy impact test, also commonly referred to as the Charpy V-notch test by material scientists, serves as a standardized high-strain rate examination to quantify the energy absorbed by a material upon fracture. The absorbed energy functions as an indicator of the material’s notch toughness.Cite this chapter. Subhash, G., Ridgeway, S. (2018). Charpy Impact Testing. In: Mechanics of Materials Laboratory Course. Charpy impact testing (also known as the Charpy v-notch test) is a high strain rate testing standard that determines the amount of energy absorbed by a material during a fault (Kim et al., 2015).Omar Gonzalez December 11, 2019 MET 2200 Dr. Stan Trout Charpy Impact Experiment Lab Report Abstract: The purpose of impact testing is to determine the nature and extent of material deformation under rapid loading conditions as well as the energy absorbed during impact. Impact testing is performed for two reasons. First, impact testing is used to compare the dynamic .

charpy impact test sample dimensions

Chaerul Umam Wardani et al in 2009, analyzed the impact testing of the Izod and Charpy methods using ST37 aluminum and steel test specimens. In the Charpy test, a sample of material is laid horizontally, then pounded by a free-falling hammer from a certain height. 1 Abstract In this experiment, the Charpy Impact test was conducted in order to determine the impact energy (K) absorbed by the Steel samples at 3 different temperatures. The Charpy impact test consists of a hammer attached to a rod which swings from an initial height creating a pendulum motion. The impact energy depends on gravity, mass, and the .

EGME 306A Experiment 5 – Charpy Impact Figure A-2: Impact Energy vs. Temperature Right Station From figures A-1 and A-2 we can see the relationship that impact energy has with temperature. We can see that 1018 steel has the .To conduct Charpy V-notch impact test and determine the ductile-brittle transition temperature of steels. Equipment . (the questions will be answered in the lab report) 1. Give the estimated values of DBTT for your steel. Suggest 2 ways in . Abstract, Introduction, etc. 3. Introduction section: . What are fatigue properties.. 1 Abstract: The primary objectives of Lab 2 & 3 was to investigate material hardness, impact resistance and tensile strength in 2024 aluminum and 1040 steel samples. The characteristics of these materials were measured with the Rockwell Hardness Test, Charpy Impact Test, and a tensile test. For the Rockwell Hardness and Charpy Impact tests, the . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm.

3 CHARPY IMPACT TEST Abstract . This lab report details the theory, observations and discussions of impact tests performed on low carbon steel samples. The temperature and the energy necessary to break each sample were as follow. For the sample at temperature of -196 oC the energy absorbed was 1.00 ft-lbs, at temperature of 0 oC the . The Izod test uses notched specimens similar to Charpy but while the Charpy impact test restricts the movement of both ends of the specimen, the Izod test only restricts one of the ends [42 . Metallic materials Abstract The maximum forces measured by the machines in this round robin are in good agreement. . NIST Interagency/Internal Report (NISTIR) - 6652. Report Number. 6652. Issue. NISTIR 6652. . McCowan, C. , Splett, J. and Lucon, E. (2008), Dynamic Force Measurement: Instrumented Charpy Impact Testing, NIST Interagency/Internal Report .

universal pendulum impact testing machine

Abstract. This review provides an overview of experimental impact testing and numerical impact simulations for composite materials in terms of a complementary combination of both techniques. . Other low-velocity impact testing methods include Charpy and Izod, which use a pendulum hammer to strike and fracture a test specimen from a fixed .Table 1 is a summary of the materials in the different conditions and the results from the Charpy test in each condition. The 1018 material showed similar properties in the lower temperatures in how the material broke. However, the material changed from brittle to ductile in the cold-finished sample around 100 ° C. Fig. 2 shows how the impact energy changed in how the material.

In the case of destructive tests, the bending strength was determined first, then the impact energy test within the framework of the Charpy impact test, and finally the compressive strength.In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and .

universal sand strength testing machine wikipedia

6 dias atrás · Prognósticos de Hóquei no Gelo de Amanhã, Dicas de Apostas grátis, Previsões e Prognósticos de Jogos, Head to Head (H2H), Comparação de Equipas e Estatísticas! . Este site usa cookies para melhorar sua experiência de usuário. Se você continuar neste site, estará fornecendo seu consentimento para o uso de cookies. .

charpy impact test lab report abstract|charpy impact test sample dimensions